From October 14 to 16, 2025, the "4th Perovskite Technology, Equipment and Materials Forum," organized by ASIACHEM Consulting, was held in Suzhou, China. The forum facilitated in-depth discussions on the scientific research progress, industrialization pathways, application scenarios, and market prospects of perovskite technology in China and globally. Jian Zhou, Chairman of Maxwell Technologie, was invited to attend and delivered a keynote speech titled "Maxwell Technologies' Perovskite/HJT Tandem Cell Solution".

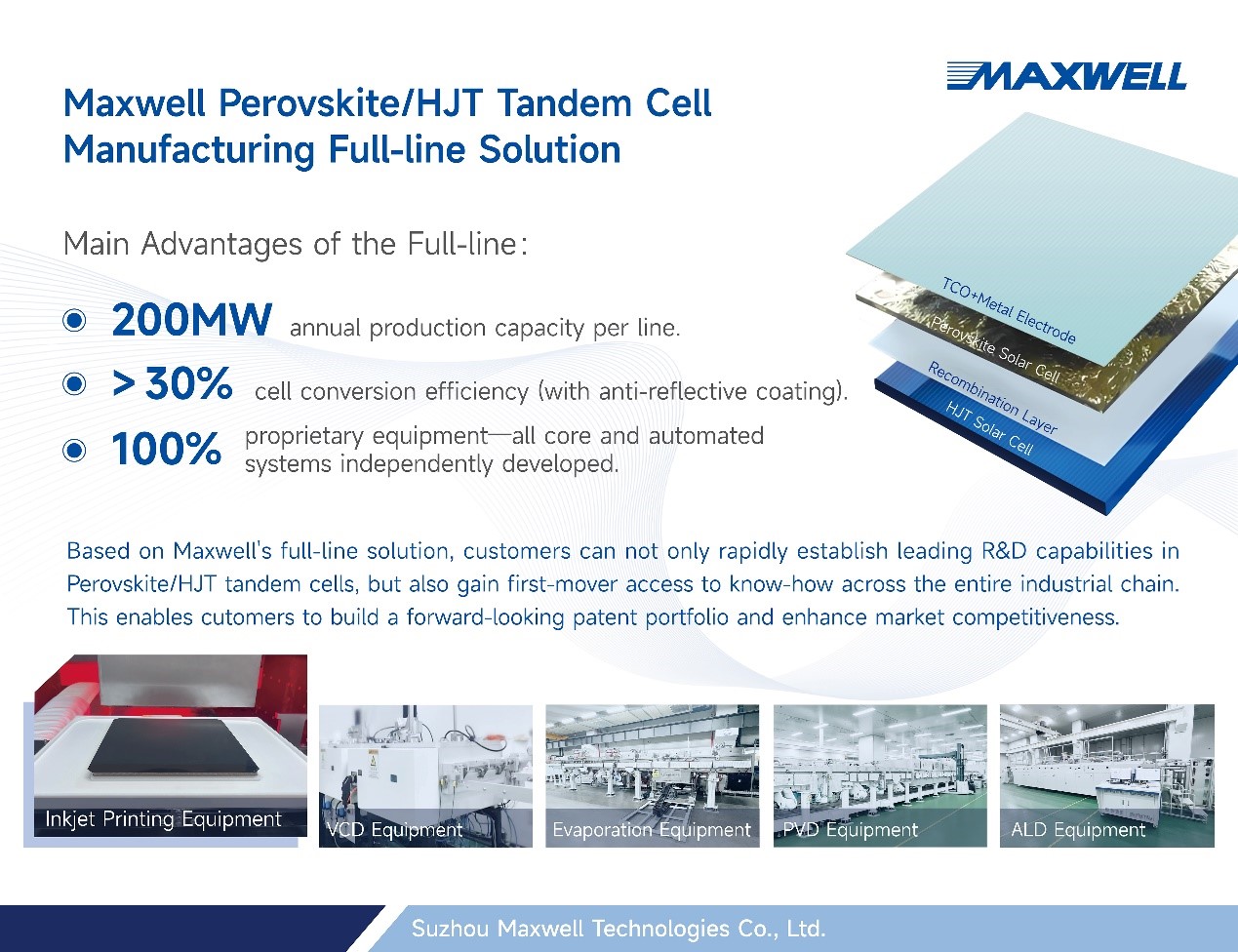

Focusing on the Company's self-developed, industry-first annual capacity 200MW large-size (G12 half-cut) perovskite/HJT tandem cell full-line equipment—a pioneering achievement in the sector—Jian Zhou presented a comprehensive introduction to the Maxwell team's continuous exploration and innovative practices in core equipment development, cell efficiency improvement, reliability assurance, and cost optimization, all aimed at accelerating the industrialization process of tandem cells.

"To do a good job, an artisan needs the best tools." Equipment is the foundation of manufacturing and a key prerequisite for transforming laboratory achievements into mass production. Jian Zhou stated, "Maxwell Technologies has extensive mass production experience in crystalline silicon cell screen printing and HJT cell full-line solutions, with equipment proven through long-term reliability validation at customer sites. In the field of perovskite tandem technology, Maxwell has deployed a range of specialized and extended technologies to support the industry in establishing the first 100-MW-level pilot line through standardized full-line solutions—serving as a high-stability, high-reliability demonstration platform to consolidate the foundation for continuous optimization in materials, processes, and power generation applications".

In his presentation, Jian Zhou also highlighted several technical innovations of Maxwell’s tandem cell full-line solution, including customized production capacity scale design, core vacuum technology, pre-printing technology, facility-equipment integration, inkjet printing, EAP INLINE layout and photon sintering, etc.

Key Advantages of Maxwell’s Perovskite/HJT Tandem Cell Full-line Solution

Customized Production Capacity Scale Design: Based on the Company's globally leading HJT 600MW+ mass production technology platform, Maxwell can flexibly configure the production capacity of the tandem cell full line, offering 20~50MW lab lines, 100~200MW pilot lines, and 500~600MW mass production lines, precisely matching customer R&D and production needs.

Core Vacuum Technology Platform: With seven years of experience in plate-type vacuum systems and more than 3,000 PECVD and PVD chambers delivered, Maxwell’s vacuum platform ensures high stability, low breakage rates, and minimal downtime, enabling customers’production lines to run continuously and efficiently.

Pre-printing Technology: Exclusively developed by Maxwell, the pre-printing process completes P-side grid line printing before perovskite film formation, leveraging mature HJT printing processes and silver/silver-copper paste systems. This innovation significantly reduces material costs while improving cell efficiency by 0.5%~1.0%.

Facility-Equipment Integration: By integrating key utilities within the equipment, Maxwell greatly reduces low-humidity room construction and HVAC operation costs, while improving cell efficiency and stability — achieving dual optimization of investment and operating expenses.

Inkjet Printing Technology: Maxwell’s fully automated inkjet printing process delivers over 95% material utilization with excellent film conformality, uniformity, integrity, and edge control throughout the perovskite wet process.

EAP INLINE Layout: By connecting three key process modules — evaporation, ALD, and PVD/PED — via automated transfer systems, Maxwell’s INLINE layout triples production efficiency compared with traditional configurations.

After in-depth comparison of temporal and spatial ALD, Maxwell adopted the more efficient temporal approach, supported by patented designs that reduce material consumption and boost throughput.

Photon Sintering Technology: Through precise temperature control, the photon sintering process maintains a temperature differential of over 30°C between the paste and wafer, reducing grid resistance while protecting the perovskite layer from thermal damage — further enhancing cell conversion efficiency.

Guided by a clear “Full-Line Technology Roadmap,” Zhou concluded: "Although full industrial maturity of the perovskite/silicon tandem value chain will take time, Maxwell will continue driving synergy across all segments through its full-line equipment and technical solutions — accelerating the path toward scalable mass production and empowering the photovoltaic industry to achieve higher efficiency and lower cost."

About Maxwell

Suzhou Maxwell Technologies Co. Ltd. (‘Maxwell’ or ‘Maxwell Technologies’) is a high-end equipment manufacturer in the pan-semiconductor industry, possessing independent R&D capabilities in core technologies such as vacuum, laser, precision engineering, software, and automation. In the solar PV industry, Maxwell specializes in advanced production solutions including full-automatic solar cell metallization lines, HJT cell manufacturing equipment and perovskite/HJT tandem cell manufacturing full-line solution, etc.

Founded in 2010, Maxwell has over 5000 employees and customers include the world’s leading solar manufacturers, including Tongwei Solar, Trina Solar, Longi, JA Solar, Jinko, Canadian Solar, etc.

Contact of Maxwell

Sky Sheng

PV Sales Director

+86 0512-6166 8888

+86 150 2100 2367

shengchenxin@maxwell-gp.com